We call Ultraviolet Panel “UV panel.” This name comes from the first letters of “Ultraviolet.” Ultraviolet light is key in its production.

UV panels use materials like medium-density fiberboard (MDF) and plywood. These materials provide stability. They also make the panels easy to work with.

Manufacturers apply a UV coating to the panel surface. Then, they use ultraviolet light to quickly dry and harden this coating. This process creates the UV wall panel.

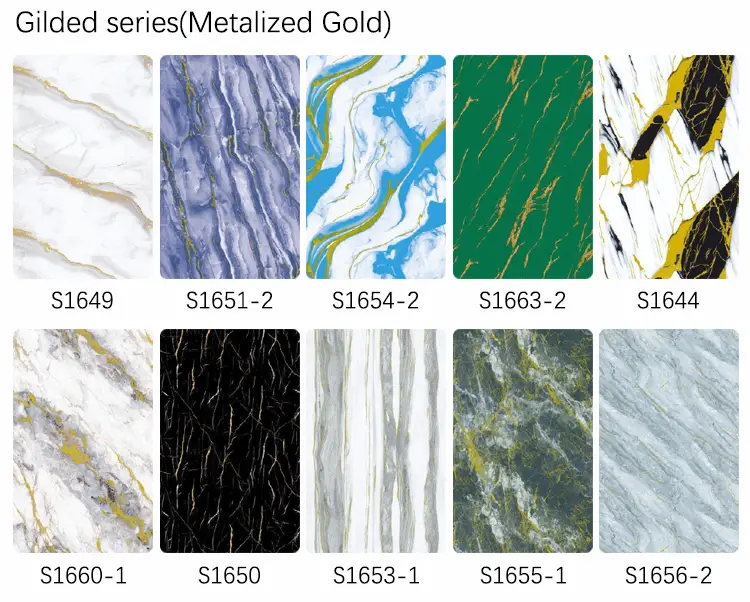

UV wall panels come in many vibrant colors. The UV paint can also mimic natural materials. Wood grain and stone grain are common examples. This gives many design options for interiors. You can meet different style needs easily.

High-gloss UV panels create a luxurious feel. Matte panels offer a softer look. You can choose based on the space and your taste.

The UV coating hardens under ultraviolet light. This makes the panel surface very hard. It resists scratches and impacts well. Daily use does not easily damage it. The panel maintains its good appearance.

Production ensures UV wall panels have a very flat surface. After installation, walls look smooth. There are no waves or bumps. This improves the overall look of the decoration.

Compared to stone and tiles, UV panels weigh less. This makes them easy to carry and install. They also reduce the load on walls. This is helpful in high-rise buildings. Lightweight partitions also benefit.

UV paint has good chemical stability. It resists acids and alkalis. In kitchens and bathrooms, UV panels perform well. They do not easily corrode or change color.

The surface film resists stains because it repels water. Dirt does not stick easily. You can clean it with a damp cloth. Oil and ink also do not penetrate easily.

During production, UV paint cures with ultraviolet light. This releases very few VOCs. This meets national environmental standards. It helps create a healthy indoor environment. It reduces harm to people and the environment.

UV wall panel base materials like wood are often recyclable. At the end of their life, you can recycle them. This reduces environmental impact. It supports sustainable development.

UV panels often have a modular design. Their sizes are standard. You can directly join them during installation. Special connectors can also fix them to walls. Complex work is not needed. This shortens installation time. It also improves efficiency. Their light weight also reduces physical effort for installers.

UV coatings offer many colors and textures. They can also look like natural stone and wood. This meets different decoration style needs.

Regular UV panel size is 1220×2440×n millimeters.

This information should help you understand UV panels for interior design projects and modern wall finishing solutions. We hope this comprehensive guide to UV wall panels is useful. Thank you for learning about durable and decorative UV interior panels. Consider affordable UV wall panel options for your next project. Explore the benefits of UV coated wall boards today.