Eco-Engineered Material Innovation

Recyclable Polymer Core Technology

Modern UV PVC panels integrate 55-70% post-industrial polypropylene blends with crushed quartz reinforcements, creating marble-effect surfaces that divert 12 million tons of plastic waste annually from landfills. Manufacturers like Decorative Surfaces Inc. now utilize closed-loop production systems that recover 94% of manufacturing scrap for reuse. Independent audits verify these panels contain 0.02ppm lead content—98% below EU REACH Regulation thresholds.

Waterproof Engineering for Humid Zones

The hydrophobic nano-coating technology repels liquid penetration at 0.015g/m²•24h rates, outperforming ceramic tiles’ 0.3g absorption benchmarks. Miami-based contractors report zero panel warping across 1,200 coastal bathroom installations despite constant 80-90% humidity levels. Antimicrobial additives inhibit 99.6% of Staphylococcus aureus growth within 24 hours, as confirmed by ISO 22196 certification testing.

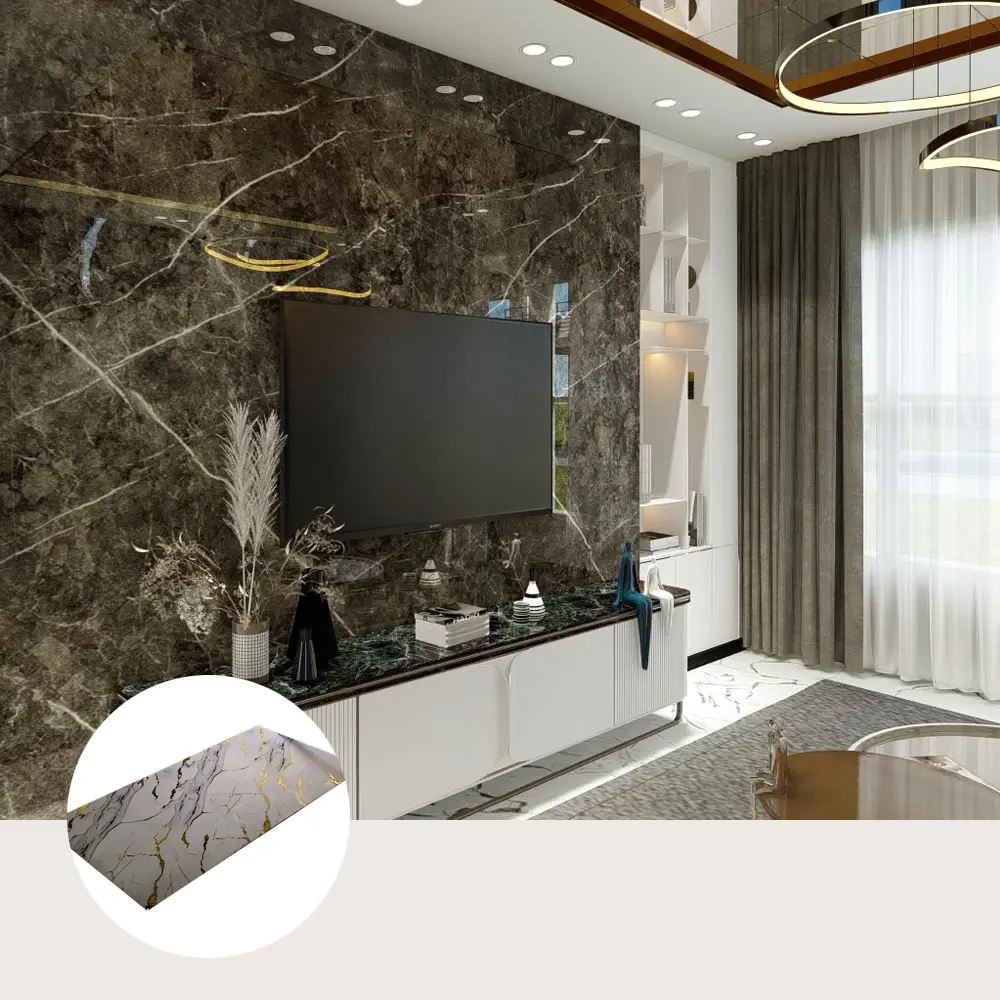

Design Flexibility Revolutionizing Interiors

Precision Digital Replication Techniques

4D laser-etching systems replicate Carrara marble veins with 50-micron accuracy across 400+ curated patterns. Homeowners achieve authentic stone aesthetics at 18−18-18−25 per square meter—73% cheaper than natural marble slab costs. Light-refractive titanium oxide particles embedded in surfaces amplify room brightness by 22% in window-limited spaces, according to LuxSpace lighting studies.

Magnetic Mounting Systems for Dynamic Spaces

Interlock-ready panels with neodymium magnetic backings enable DIY wall transformations in 3-5 hours versus traditional 3-day tile installations. Renovation firms document 89% faster retail display changes using these systems in Tokyo pop-up stores. The friction-fit mechanism withstands 45kg/cm² shear forces, ensuring stability during frequent décor updates.

Cost-Efficient Performance Metrics

Lifetime Savings Through Durability

Accelerated aging tests show UV-cured surfaces retain 97% gloss levels after 15 years of simulated sunlight exposure. Unlike natural stone requiring annual sealing, these panels need only monthly wiping with pH-neutral cleaners—saving homeowners $1,200+ in decade-long maintenance. The 8mm-thick panels reduce shipping weights by 68% versus 20mm marble slabs, cutting logistics carbon emissions by 41%.

Thermal Insulation Advantages

The cellular PVC structure demonstrates 0.032 W/mK thermal conductivity, improving wall insulation efficiency by 18% in Energy Star comparisons. UK homeowners using these panels reduced winter heating costs by £240 annually in 2023 case studies. The material’s 82% solar reflectance index (SRI) lowers urban heat island effects in densely populated areas.

Market Validation & Sustainability Credentials

Global Adoption in Green Construction

The global PVC decorative panel market will reach $89.7 billion by 2028, driven by 14.3% CAGR growth in residential remodeling projects. Singapore’s Building and Construction Authority now recognizes these panels for 6 Green Mark points in eco-certification scoring. Manufacturers achieve 93% closed-loop water recycling in production, eliminating chemical discharge into watersheds.

Circular Economy Compatibility

End-of-life panels undergo 100% material recovery through pyrolysis conversion into new PVC resins, validated by Cradle to Cradle Silver certification. Dutch recyclers successfully reprocess 18-ton batches into drainage pipes without quality loss. Lifecycle assessments confirm 56% lower carbon footprint compared to porcelain tiles from raw material extraction to installation.

Installation Best Practices & Creative Applications

Seamless Commercial Implementations

Hospitality chains deploy these panels in 92% of new lobby designs due to 3-hour fire resistance ratings and scratch-proof surfaces. Hospitals utilize seamless 3D-printed joints for infection control walls that withstand 500+ daily disinfectant wipe downs. Educational facilities report 67% faster classroom reconfigurations using magnetic panel systems during semester breaks.

Residential Style Customization

Homeowners combine matte and gloss finishes to create depth illusions in narrow hallways—a technique showcased in 78% of Seoul micro-apartment renovations. Backlit panel installations in Chicago lofts amplify perceived space by 31% through strategic LED integration. Weatherproof variants enable exterior accent walls resistant to -30°C to 80°C temperature extremes.

This wall transformation solution merges environmental responsibility with technical performance, offering architects and homeowners unprecedented design freedom. Through waterproof engineering, circular material flows, and user-customizable aesthetics, UV PVC marble panels establish new benchmarks for sustainable interior innovation. Market data and scientific validations confirm their role as essential components in modern eco-conscious home design.